The trend for digitalization,including increased connectivity and IoT, is growing among industrial organizations such as power plants, manufacturers, and water treatment centers, which rely on industrial control systems (ICS) for their operations.

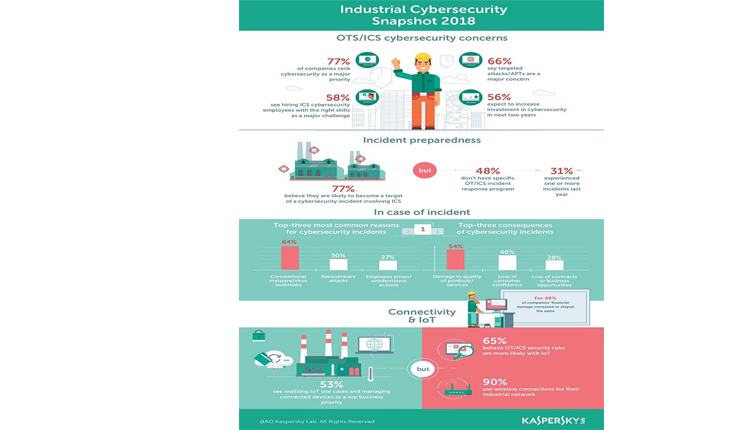

It’s a trend that comes with acknowledged cybersecurity dangers – 65% of companies believe that ICS security risks are more likely with IoT.

Yet, Kaspersky Lab has also unearthed a contradiction among the industrial community. The company has found that many organizations are keen to boost the efficiency of their industrial processes with new IT, and although they are investingin securityf or their IT networks, they are leaving the doors to their operational technology (OT) wide open.This is allowing basic threats such as ransomware and malware to step right in and catch them out. These, and other findings, have been unveiled today in Kaspersky Lab’s ‘State of Industrial Cybersecurity 2018’ report.

The convergence of IT and operational technology (OT),the wider connectivity of OT with external networks,andthe growing number of Industrial IoT devices,is helping toboost the efficiency of industrial processes. However, these trends bring growing risks and points of vulnerability, leading industrial organizationsto feel unsafe -over three quarters (77%) of companies believe their organization is likely to become the target of a cybersecurity incident involving their industrial control networks.

Organizations are leaving a gap in the way they approach cybersecurity in their IT and OT/ICS networks. Even though they have an understanding of the risks associated with increased digitalization, they are not putting the right cybersecurity practices in place to protect their operational networks.

51% of industrial companies claim that they were not affected by any cybersecurity incidents in the last year.With half of the research respondents working in the IT department, this finding suggests that IT managers maybe unaware of incidents happening within their own industrial control systems– perhaps because they lack a unified approach to their organization’s overall cybersecurity. There is also room for better integration between IT and OT cybersecurity – a fact highlighted by the discovery that 48% of organizations admit they have no measures in place to detect or monitor if they have suffered an attack concerning their industrial control networks.

These attacks could lead to catastrophic circumstances, including damage to products, loss of customer confidence and business opportunities, or even environmental damage and loss of production at one or multiple sites. For those that have been the victim of at least one ICS cybersecurity incident over the past 12 months, 20% say the financial damage to their business has increased, giving a further incentive to invest in better cybersecurity systems.

Risks perception vs reality: breached by employee mistakes

Despite the awareness and dedicated spend on advanced IT security in the sector, the OT systems of industrial organizations are still getting caught out by conventional and mass malware attacks. While concern has grown around the risk of targeted attacks, almost two-thirds (64%) of companies experienced at least one conventional malware or virus attack on their ICS in the last 12 months. 30% of companies suffered a ransomware attack and a quarter (27%) had their ICS breached due to the errors and actions of employees. Targeted attacks affecting the sector accounted for just 16% in 2018 (down from 36% in 2017), suggesting that the concern and reality around the risks of targeted attacks is misplaced, and that companies relying onICS are still falling victim to more conventional threats, including malware and ransomware, as well as targeted attacks.

“With the sector embracing more digital trendssuch as cloud and IoT to further drive efficiencies, the challenge and importance of cybersecurity becomes even more vital, to keep critical systems running and businesses operational. The good news is that we are seeing more and more businesses improving their cybersecurity policies, to include dedicated measures towards safeguarding their industrial control networks. While this is a step in the right direction, action needs to go further to keep up with the pace of digitalization. This includes updating incident response programs to cover specific ICS actions and using dedicated cybersecurity solutions to help meet the challenge,” saysGeorgy Shebuldaev, Brand Manager, Kaspersky Industrial Cybersecurity.

Future challenges: IoTand cloud

The adoption of Industrial Internet of Things and cloud-based systems have added a new security dimension into the mix, which is proving a challenge for industrial businesses. For over half of companies (54%), the increased risks associated with connectivity and the integration ofIoT ecosystems is a major cybersecurity issue for the year ahead, as well as the implementation of measures to manage it.

With companies investing in further smart technologies and automation, and the adoption of industry 4.0, the trend for connectivity and IoT is only going to increase. Indeed, when it comes to cloud deployment, 15% of industrial organizations already use cloud solutions for SCADA control systems, with a further 25% planning to implement these in the next 12 months. This is leading to a considerable drive towards using cloud for the high-level management of critical infrastructure.

It is therefore vital that cybersecurity measures keep up with the rate of technology adoption, to ensure that the rewards outweigh the risks for the organizations involved.Businesses need to take ICS incident response programs more seriously, to avoid risking severe operational, financial and reputational damage. Only by developing a specific incident response program and using dedicated cybersecurity solutions to manage the complex nature of the connected and distributed industrial ecosystems, can businesses keep their services and products, customers and environment safe.

It’s a trend that comes with acknowledged cybersecurity dangers – 65% of companies believe that ICS security risks are more likely with IoT.

Yet, Kaspersky Lab has also unearthed a contradiction among the industrial community. The company has found that many organizations are keen to boost the efficiency of their industrial processes with new IT, and although they are investinginsecurityfor their IT networks, they are leaving the doors to their operational technology (OT) wide open.

This is allowingbasic threats such as ransomware and malware to step right in and catch them out. These, and other findings, have been unveiled today in Kaspersky Lab’s ‘State of Industrial Cybersecurity 2018’ report.

The convergence of IT and operational technology (OT),the wider connectivity of OT with external networks,andthe growing number of Industrial IoT devices,is helping toboost the efficiency of industrial processes. However, these trends bring growing risks and points of vulnerability, leading industrial organizationsto feel unsafe -over three quarters (77%) of companies believe their organization is likely to become the target of a cybersecurity incident involving their industrial control networks.

Organizations are leaving a gap in the way they approach cybersecurityin their IT and OT/ICS networks. Even though they have an understanding of the risks associated with increased digitalization, they are not putting the right cybersecurity practices in place to protect their operational networks. 51% of industrial companiesclaim that they were not affected by any cybersecurity incidentsin the last year.Withhalf of the research respondents working in the IT department, this finding suggests thatIT managers maybe unaware of incidents happening within theirown industrial control systems– perhaps because they lack aunifiedapproach to theirorganization’s overall cybersecurity. There is also room for better integration between IT and OT cybersecurity – a fact highlighted by the discovery that 48% of organizations admit they have no measures in place to detect or monitor if they have suffered an attack concerning their industrial control networks.

These attacks could lead to catastrophic circumstances, including damage to products, loss of customer confidence and business opportunities, or even environmental damage and loss of production at one or multiple sites. For those that have been the victim of at least one ICS cybersecurity incident over the past 12 months, 20% say the financial damage to their business has increased, giving a further incentive to invest in better cybersecurity systems.

Risks perception vs reality: breached by employee mistakes

Despite the awareness and dedicated spend on advanced IT security in the sector, the OT systems of industrial organizations are still getting caught out by conventional and mass malware attacks. While concern has grown around the risk of targeted attacks, almost two-thirds (64%) of companies experienced at least one conventional malware or virus attack on their ICS in the last 12 months. 30% of companies suffered a ransomware attack and a quarter (27%) had their ICS breached due to the errors and actions of employees. Targeted attacks affecting the sector accounted for just 16% in 2018 (down from 36% in 2017), suggesting that the concern and reality around the risks of targeted attacks is misplaced, and that companies relying onICS are still falling victim to more conventional threats, including malware and ransomware, as well as targeted attacks.

“With the sector embracing more digital trendssuch as cloud and IoT to further drive efficiencies, the challenge and importance of cybersecurity becomes even more vital, to keep critical systems running and businesses operational. The good news is that we are seeing more and more businesses improving their cybersecurity policies, to include dedicated measures towards safeguarding their industrial control networks. While this is a step in the right direction, action needs to go further to keep up with the pace of digitalization. This includes updating incident response programs to cover specific ICS actions and using dedicated cybersecurity solutions to help meet the challenge,” saysGeorgy Shebuldaev, Brand Manager, Kaspersky Industrial Cybersecurity.

Future challenges: IoTand cloud

The adoption of Industrial Internet of Things and cloud-based systems have added a new security dimension into the mix, which is proving a challenge for industrial businesses. For over half of companies (54%), the increased risks associated with connectivity and the integration ofIoT ecosystems is a major cybersecurity issue for the year ahead, as well as the implementation of measures to manage it.

With companies investing in further smart technologies and automation, and the adoption of industry 4.0, the trend for connectivity and IoT is only going to increase. Indeed, when it comes to cloud deployment, 15% of industrial organizations already use cloud solutions for SCADA control systems, with a further 25% planning to implement these in the next 12 months. This is leading to a considerable drive towards using cloud for the high-level management of critical infrastructure.

It is therefore vital that cybersecurity measures keep up with the rate of technology adoption, to ensure that the rewards outweigh the risks for the organizations involved.Businesses need to take ICS incident response programs more seriously, to avoid risking severe operational, financial and reputational damage. Only by developing a specific incident response program and using dedicated cybersecurity solutions to manage the complex nature of the connected and distributed industrial ecosystems, can businesses keep their services and products, customers and environment safe.